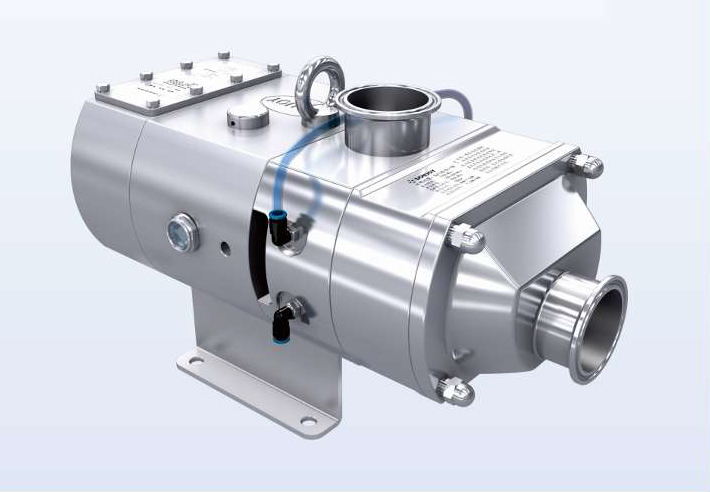

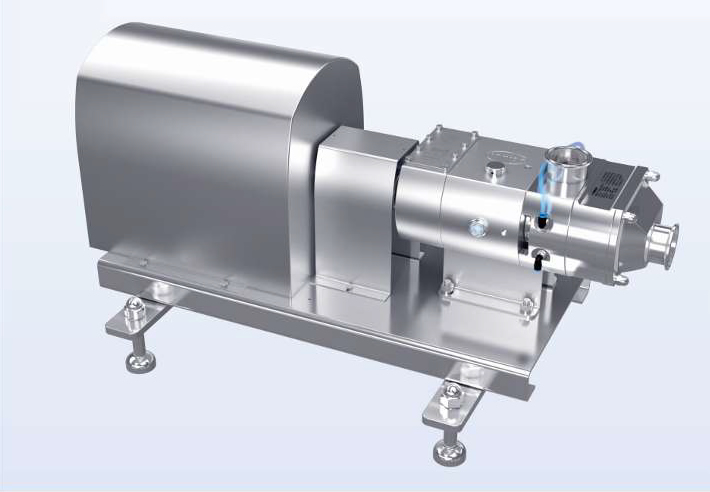

Flexible solution tor two-direction reversible, high pressure, high viscosity, large particle, pulse free, liquid delivery.

Twin-screw pump has strong self-priming ability, can transport solid particles. gas-liquid mixture, high viscosity. low viscosity and othermaterials. The pump not only can extract and convey materials, but also apply tor CIP and SIP systems, can reduce pipeline, valve and CIP exclusive pumps, which improve efficiency and save cost. it has extra characteristics, that other volume pumps do not have. such as no pulse phenomenon, no particlo damago, high pressure, wide speed range, large flow range and so on.

Food and Beverage

Soup, stew, ketchup, vegetables, condiments, chocolate, fat and oil, cream fılling, breweries, wort, brewery, wort, soft drink/fruit juice, moat procossing.

Dairy

Cream, milk, choese curd and whey, cottage cheese, yogurt.

Medicine/Cosmetic

Ointment, syrup, extractıve, serum, face creams & emulsıon, hair stylıng gels & liquids, dyes and alcohols, soap, cosmetics.

Max Fow ………………………: 110 m3/h

Max Particles……………….: 23mm

Max Pressure……………….: 20bar

Speed Range…………………: 10-3500 R.P. M.

Material………………………..: %100 SS316L Stainless Steel

Working Temperature…: -40 °C ve 15 °C

Suiface Lreatmerıt……….: Ra≤0.6 μ m; Ra≤0.4 μ m

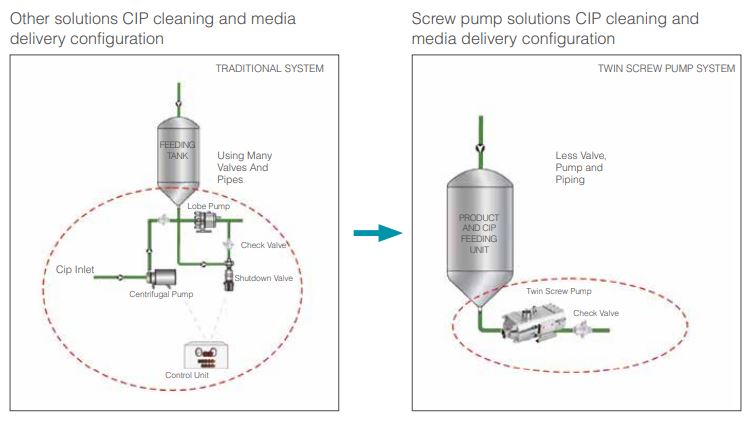

After used screw pump, other auxiliary pumps and valves and controllers can be reduced as more as possible

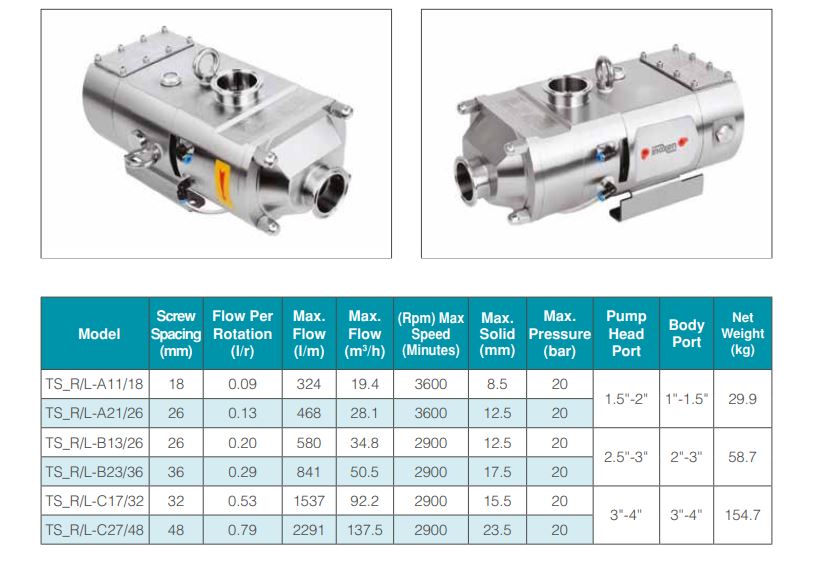

Choose the right screw spacing for your process

Option 1: Large screw spacing, larger flow rate. Can deliver larger particles, but the pressure will be lower compared with small spacing screw.

Option 2: Small screw spacing, lower flow rate but higher pressure, the particles that can be transported will also be smaller.